End of Arm Tooling

FEATURES AND BENEFITS OF END OF ARM TOOLING

End of arm tooling is what makes a collaborative robot effective and is critical to the success of your specific application. By leveraging our comprehensive range of end of arm tooling products, your collaborative robot process can benefit from increased efficiency, improved precision, flexibility in changeovers and scalability, and seamless integration. Our end of arm tooling products and solutions are designed to meet the highest standards to ensure that you can achieve the maximum optimization from robotics investment.

TYPES OF END OF ARM TOOLING

Grippers

EFP offers a complete range of collaborative robot grippers, including electric, mechanical, vacuum, pneumatic and magnetic options to fit your specialized application. Through our global and local support teams, we’re able to provide an effective and cost-effective gripping solution for your application’s needs.

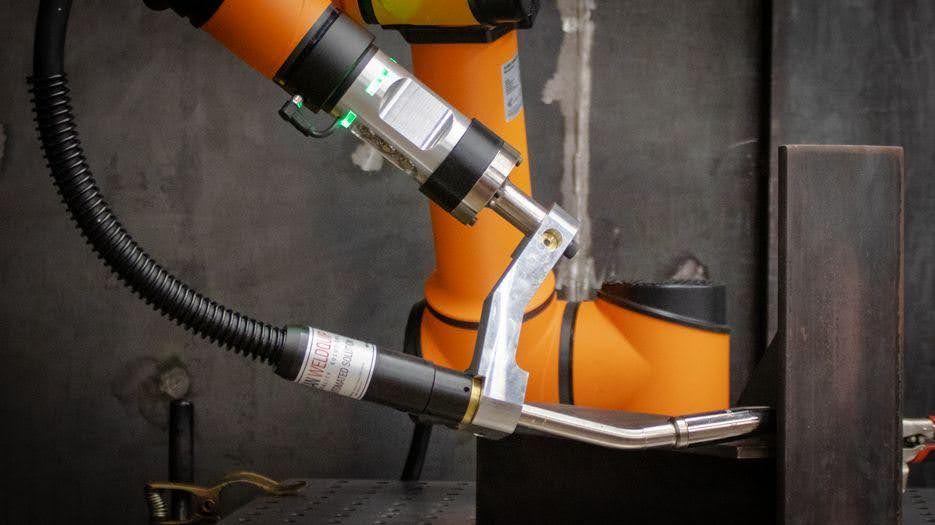

Welding and Plasma Cutting

The SwitchWeld solution is designed by welders for welders. With SwitchWeld , EFP offers a single end of arm tooling solution that can utilized for either MIG welding or plasma cutting operations. The SwitchWeld hardware includes a control box and teach pendant, a welding torch, and a proprietary puck and joystick that allows the user to program via physical movement rather than software coding. SwitchWeld is available with multiple welding torch options designed to interface with a customer’s existing power supply, making it extremely cost effective and easy to set up.

Cameras and Vision Systems

Cameras and vision systems integrate with collaborative robots to perform tasks like inspection, measurement, and part recognition. These systems process images captured by the camera lens to determine a target object’s presence, size, shape, orientation, and texture.

Dispensing and Glueing

Dispensing and glueing end of arm tools are essential for applications requiring precise application of media such as adhesives, sealants, and lubricants. This type of tooling integrates seamlessly with robotic systems to deliver controlled and consistent dispensing, ensuring accuracy and increased throughput. Dispensing end of arm tooling is crucial for industries such as automotive, electronics, and packaging, where precise material application is critical to product performance and reliability.

Tool Changers

Tool changers are used to reduce the amount of downtime on tooling changeovers. Our tool changers feature built-in air channels and electrical connectors, making changeovers quick and easy. Tool changers are available in either manual versions (meant to be quickly changed by an operator) or automatic versions (allowing the robot to swap between different tools without the need to stop).

WHY CHOOSE OUR END OF ARM TOOLING

THE EFP EDGE

Navigating the intricacies of investing in collaborative robot solutions requires an experienced and nuanced touch. This is where EFP becomes indispensable, serving manufacturers in Ohio, Kentucky, and Indiana. Whether you need help facilitating pick-and-place processes, ensuring seamless integration of a palletizing solution, or automating your welding operations, our dedicated team stands ready to assist. We take your success personally.

Our commitment is made evident with our Rapid Response Guarantee. We promise to address online chats within 60 seconds and respond to web inquiries within 60 minutes during our normal business hours, or, we will give you $60 off your next order. From the beginning to the end of your project, we prioritize ensuring you stay on time and within budget.

Since our founding in 1975, our success has been dependent upon yours. We don’t view ourselves as another vendor; we’re a committed partner, keen on ensuring your vacuum systems meet your demands.

Experience the EFP Edge.